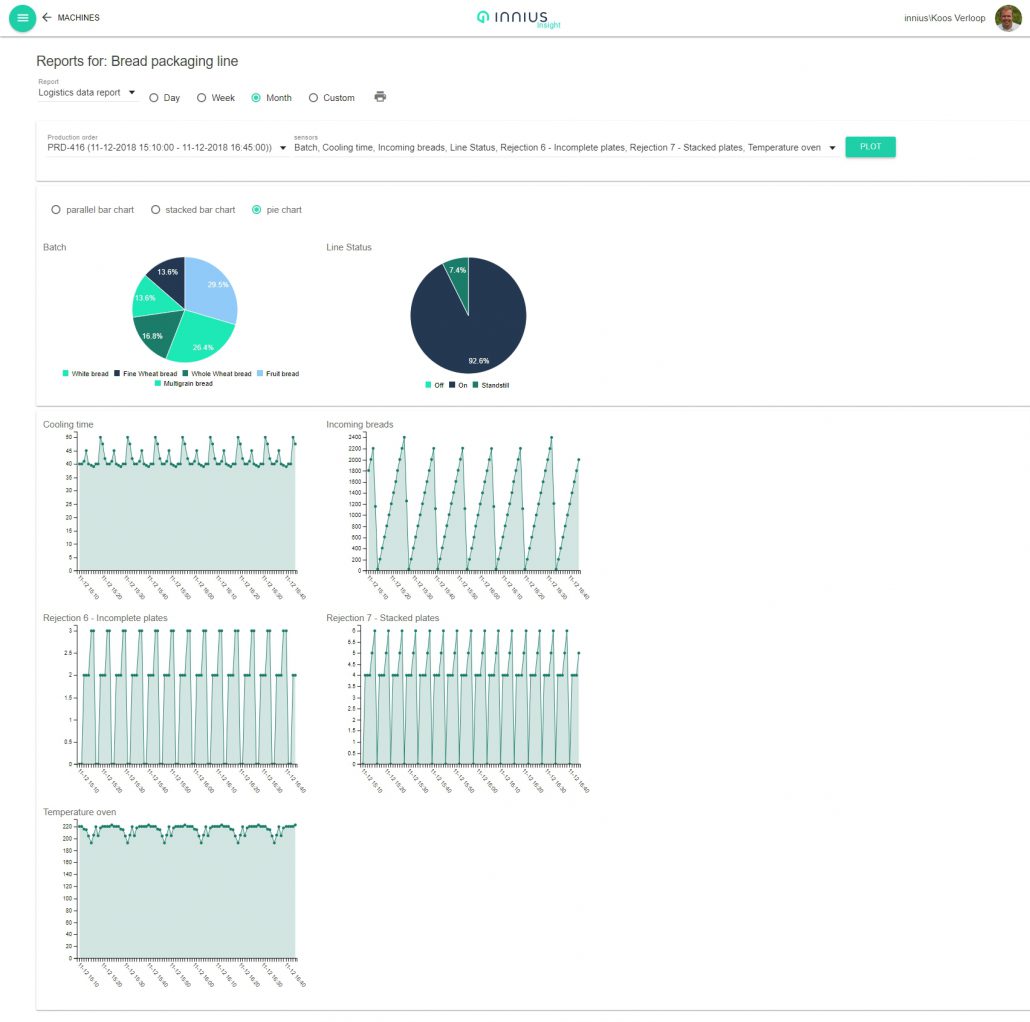

Logistics data report screenshot example

A practical example: Bakery production.

This hypothetical example explains how the logistics data report can create business value in very practical terms.

Pharos bakery has a production line producing white, wholemeal and tiger loafs of bread. The bakery uses an ERP system to generate production orders. The number of production orders and the amounts of each bread variety ordered differs day to day. Ingredients such as flour, salt and yeast, are ordered in bulk and used as each product recipe requires. There is little or no accounting for waste and spoilage.

But then the bakery adopts innius. The production line machinery, together with the ERP system are connected. Manual sensors are used in the innius Operations app to monitor waste.

Now, as each production order is finished, the production manager is able to use the logistics data report to conduct a detailed analysis of the associated machine data. This can be done quickly and easily, without having to upload and configure the data each time. Based on his findings, he is able to make the following conclusions:

- After making a batch of the wholemeal bread, the machinery requires a lot more cleaning, compared to the other bread types. This is to ensure that none of the seeds and grain contaminate other bread types.

- The energy required to mix tiger bread is 17% more than that required to mix other bread types.

- White bread loafs apparently cause the packaging machine to break down more than other types of bread, causing product spoilage.

- It’s been discovered that staff aren’t turning the ovens off between batches as procedure instructs them.

- Tiger bread results in more wastage and spoilage compared to the other bread types.

As a result, the following actions can be taken:

- Batches of wholemeal bread can be moved to the end of each shift, so that the extra cleaning coincides with the general cleaning which takes place between shifts anyway. This will save time and cut costs.

- The extra energy required to mix tiger bread will be factored into the costing.

- Decisions can be made as to where the machinery can can be optimized or replaced.

- An alert has been created within innius, to warn the production manager if the oven has been left on for more than 2 minutes without any bread inside.

- The cost prices for the different bread types have been updated to reflect the difference in wastage and spoilage costs.

The impact on the business is that Pharos bakery has been able to increase production capacity, improve the quality of its white and tiger varieties, reduced waste, and has much more accurate costings. As a result, the price of tiger bread can be slightly increased, whilst that of wholemeal and white bread can be reduced.

Want to know more?

The power of innius goes well beyond production logistics and the bakery industry. If you’d like personal advice on how innius could create value for your business, then feel free to contact me today. I look forward to hearing from you.