In oktober 2017 zijn we trotse partner geworden van het Feed Design Lab. De ambitie van Feed Design Lab is om tot een duurzame diervoederindustrie te komen. Met een proeffabriek voorzien van de nieuwste technologieën, met cursussen en innovatieprojecten biedt Feed Design Lab een omgeving aan haar partners, waarin ze haar missie realiseert.

De hoofdreden dat we partner zijn geworden is dat we met innius deze missie onderschrijven en significant kunnen bijdragen om deze missie te bewerkstellingen.

Hoe dragen we bij aan deze missie?

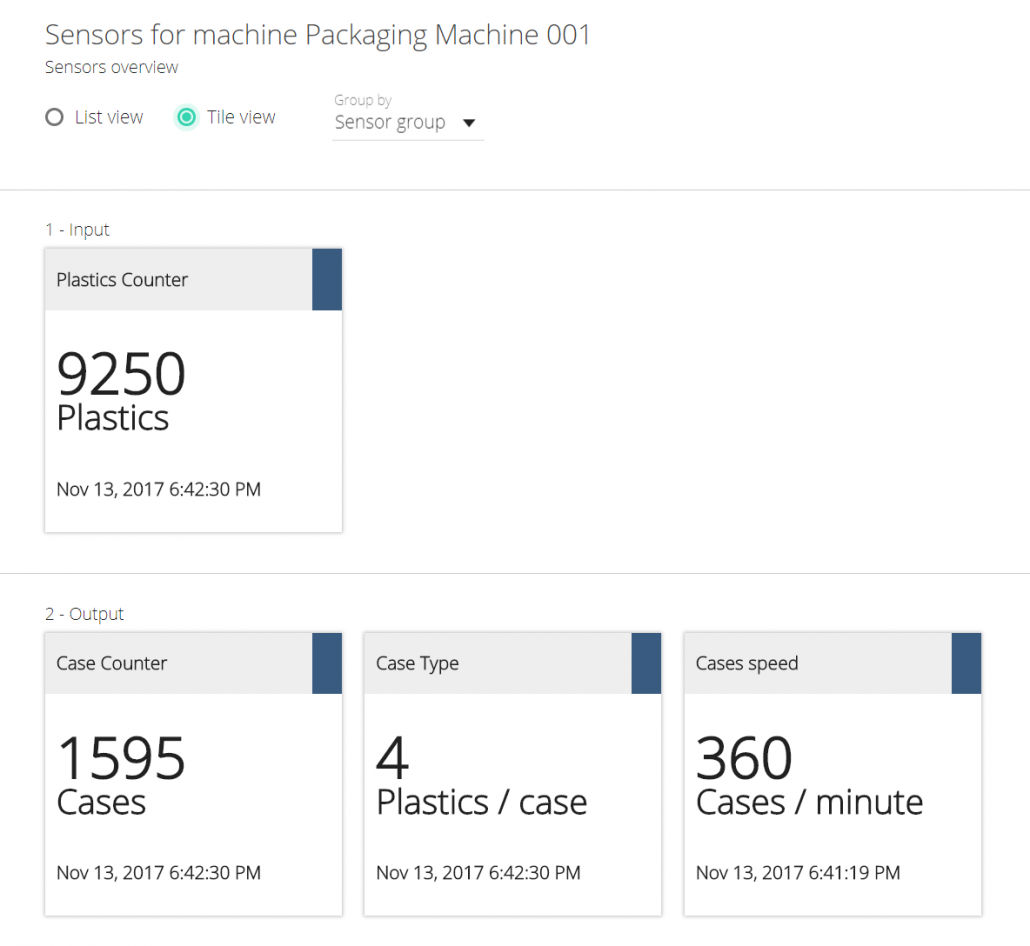

Innius is, in het kort omschreven, een software platform, dat het mogelijk maakt eenvoudig een verbinding te maken met een (diervoeder) productielijn en real-time de (machine) data van deze productielijn te analyseren, te interpreteren en acties te ondernemen.

Dit heeft als gevolg dat innius op vijf punten bijdraagt aan een duurzame diervoederindustrie. Deze vijf punten zijn:

- Verminderen van verspilling

- Verlagen van de milieu impact

- Zorgen dat het productievolume behaald kan worden

- Zorgen dat de diervoeding veilig wordt geproduceerd

- Meer productief worden

1. Verminderen van verspilling.

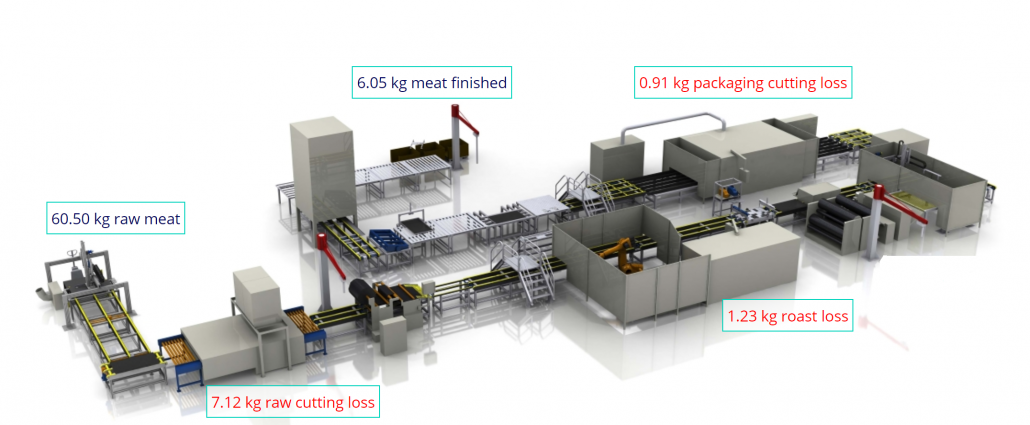

Door real-time inzicht te geven hoe een productielijn zich gedraagt, zijn we in staat inzichtelijke te maken waar verspilling in het productieproces optreedt.

Op basis van dit inzicht kan de productielijn verder geoptimaliseerd worden om de verspilling terug te dringen.

2. Verlagen milieu impact

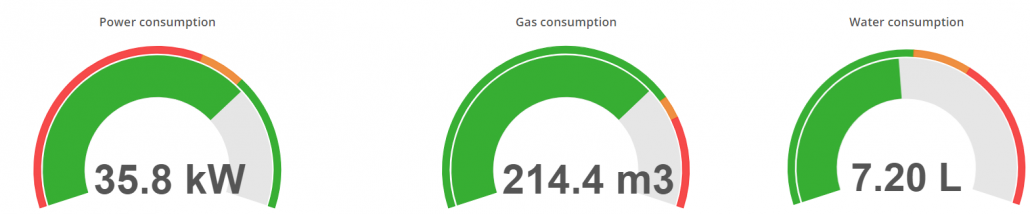

Het produceren van diervoer vraagt energie in de vorm van gas en elektriciteit. Ook water speelt een grote rol bij de productie van diervoeding.

Om de impact op het milieu tijdens het productieproces zo laag als mogelijk te houden, geeft innius aan waar energie of water wordt gebruikt. Innius maakt inzichtelijk dat dit gebruik zich binnen de afgesproken hoeveelheden beweegt. Dreigt het energie verbruik boven de gestelde drempelwaarden te komen, dan wordt de productie medewerken middels een notificatie met een bijbehorende taak hiervan op de hoogte gebracht. Hiermee wordt tijdig voorkomen dat er meer energie en water wordt gebruikt dan vastgesteld.

Ook kan er een benchmark worden opgezet met andere gelijkwaardige productielijnen, om het energieverbruik met deze productlijnen te vergelijken.

3. Zorgen dat het productievolume behaald kan worden

Real-time informatie over de productiecapaciteit en -ruimte op een productielijn geeft inzicht of de geplande productie kan worden gehaald, of dat een extra productieronde gepland kan worden. Een hogere bezettingsgraad op een productielijn zorgt voor een betere prijs per geproduceerde eenheid en een beter benutting van de productie middelen.

4. Zorgen dat de diervoeding veilig wordt geproduceerd

Onderhoud aan productielijnen en met name het schoonhouden daarvan draagt bij aan hogere (dier) voedselkwaliteit en -veiligheid (afwezig zijn van besmettingen). Met behulp van sensoren op de productielijn, gecombineerd met het onderhouds- en schoonmaakplan, worden door innius taken uitgedeeld aan productiemedewerkers die verantwoordelijk zijn voor de schoonmaak en het onderhoud. Bij het uitdelen van deze taken door innius worden instructies in de vorm van video’s of manuals meegestuurd om optimaal onderhoud of schoonmaak te garanderen.

5. Meer productief worden

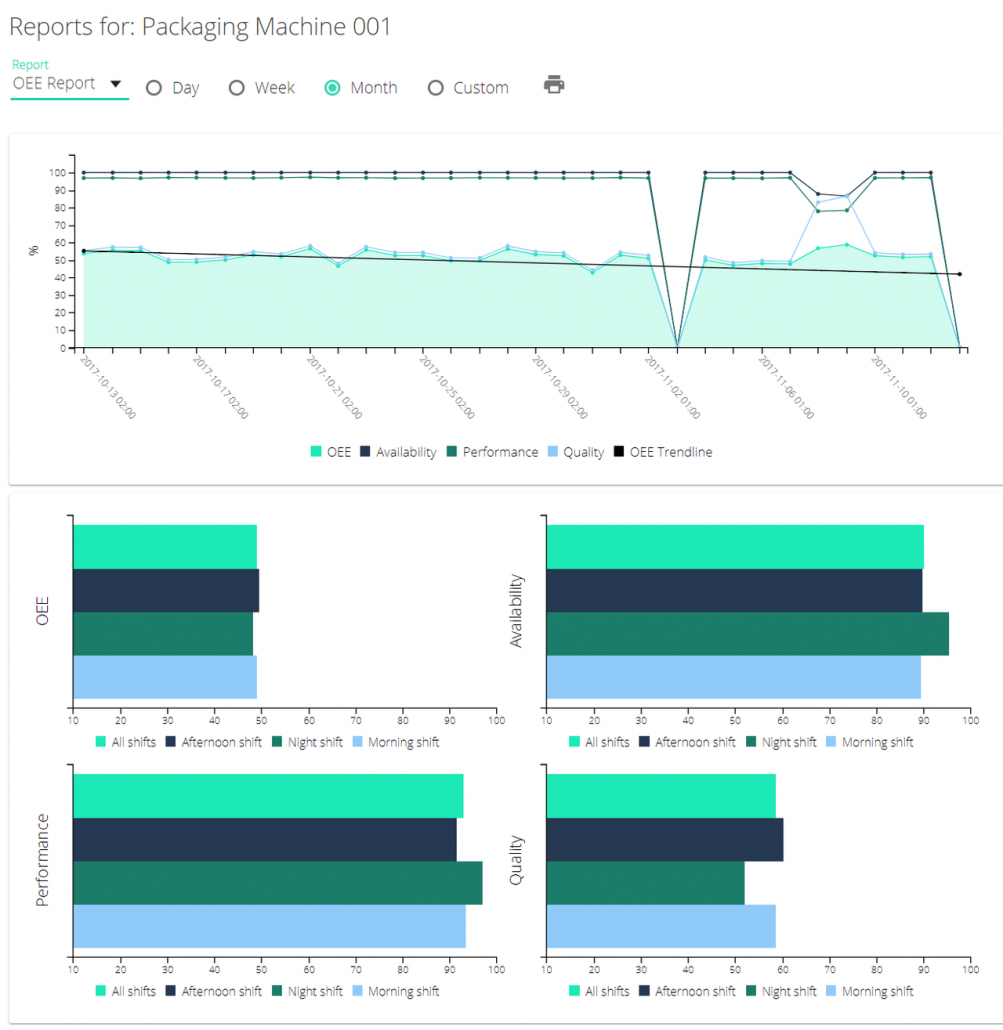

De vraag naar voedsel (voor mens en dier) neemt de komende tijd toe. Denk alleen maar aan de twee aspecten, groei wereldbevolking en toename van de welvaart in de niet westerse wereld. Om de toenemende vraag naar voedsel het hoofd te kunnen beiden is het van belang op een effectieve en efficiënte wijze voedsel te produceren. Innius bied mogelijkheden om op een zo efficiënte mogelijk wijze (dier) voedsel te produceren. Innius doet dit door o.a. inzicht te geven in de Overall Equipment Effectiveness (OEE). Deze OEE laat zien hoe efficiënt de productielijn wordt gebruikt. Tevens biedt innius detail inzicht waar verbeteringen mogelijk zijn.

Door deze verbeteringen door te voeren op de productlijn ontstaat een hogere productiviteit.

Samenvattend kunnen we stellen dat de samenwerking met Feed Design Lab en haar partners een zeer goed uitgangspunt biedt om gezamenlijk tot een duurzame diervoederindustrie te komen.