Energy Efficiency

Energy management starts with monitoring

We install sensors to control and monitor the production process. The offers enormous possibilities in analysis and monitoring. Our approach explained in six steps.

The energy sources and the associated measuring points are determined.

The measuring points of the energy flows are mapped.

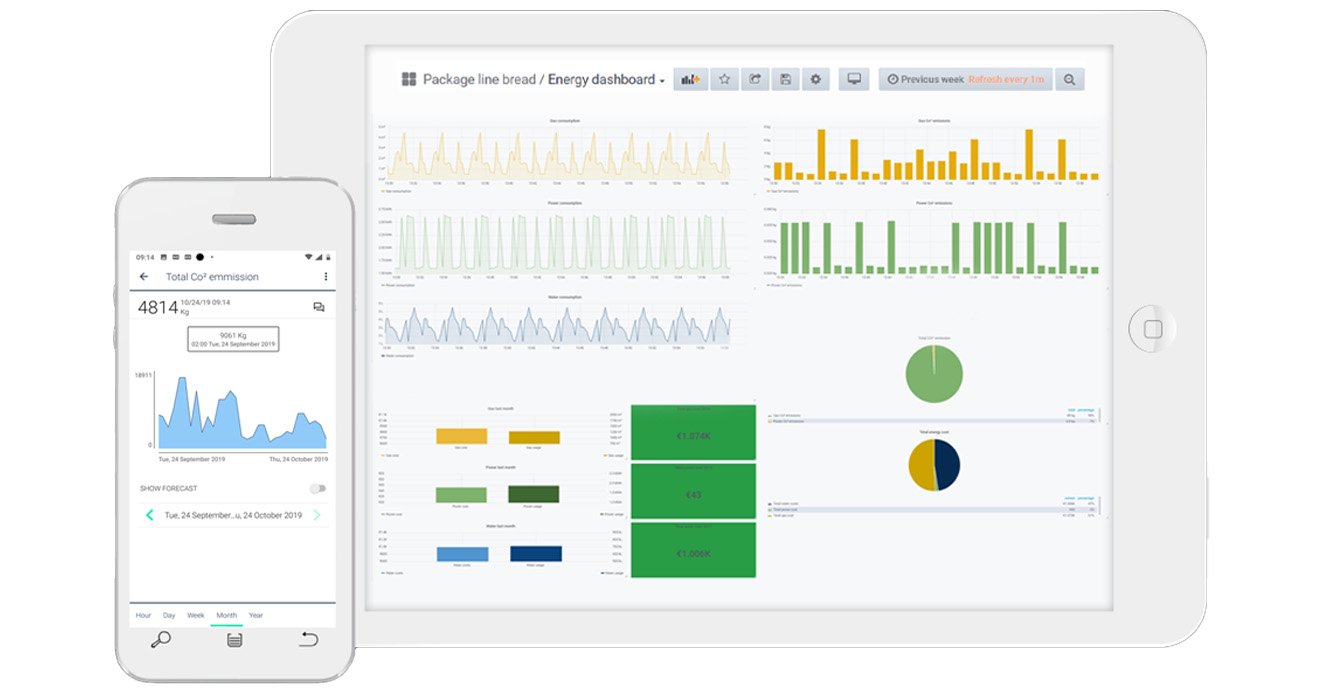

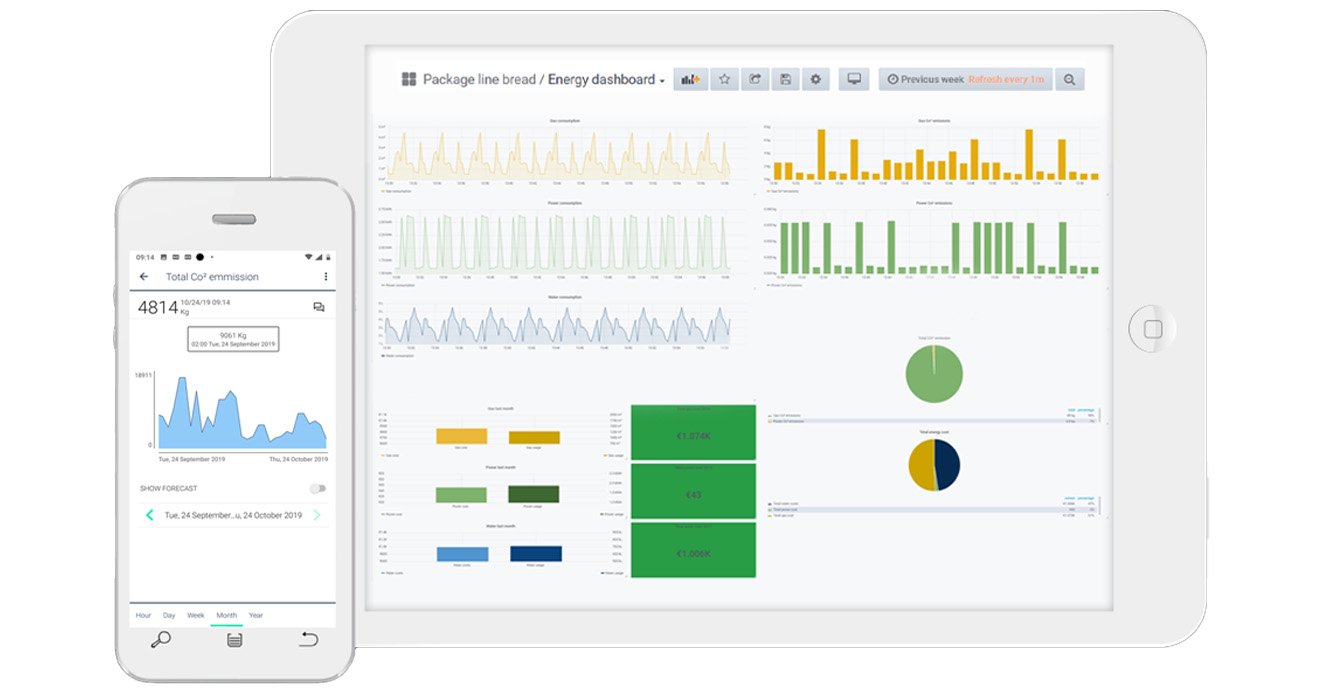

The measuring points are connected to the innius platform. This provides detailed real-time insight into your consumption and CO2 footprint.

This insight is shown to you via our apps, via smart KPIs and straightforward dashboards.

Periodic analysis studies look at the effectiveness and efficiency of consumption and identify deviations.

These analyzes form the basis for improvements. Because the consumption is measured in real-time, there is direct insight into the realized savings.

This is Richard, he’s happy to advise you! Please fill out the form and he will be in touch!